ABOUT BNG

BNG Metalmecânica is a Brazilian company founded in 1998, headquartered in the municipality of Serra – ES. It specializes in manufacturing, assembly, and industrial services, including machining of parts, components, and field machining.

With a strong presence in the Oil and Gas sector, BNG Metalmecânica also serves strategic industries such as:

- Steelmaking;

- Mining;

- Shipyards and Offshore.

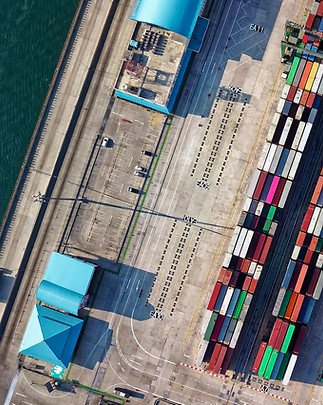

Strategically positioned with direct access to the port, BNG Metalmecânica offers efficient logistical solutions for the maritime transport of large-scale equipment, always prioritizing the quality of its products and services

OUR SERVICES

We offer comprehensive metallurgical solutions for various industrial sectors, supported by qualified teams and modern equipment.

INFRASTRUCTURE

With a site area of 99,000 m² — of which 18,000 m² are dedicated to metal structures, boiler-making, and machining — BNG Metalmecânica offers processing capacity of up to 600 tons per month, ensuring agility and precision in large-scale projects.

TOTAL AREA

99.000m²

BUILT AREA

18.000m²

PROCESSING CAPACITY

600t/m

FRONT-SEA AREA

Located within the Port of Portocel (Aracruz–ES), we have a strategically positioned front-sea manufacturing area for large structures and loading onto barges and ships. This exclusive location ensures efficient logistics for Oil & Gas clients and large-scale international projects.

OUR MISSION

MISSION

To provide metalworking products and services that ensure the availability and performance of our clients’ equipment, aiming for their loyalty by employing innovative technology, respecting the environment, and adding value and satisfaction to partners, suppliers, and employees.

VISÃO

To be a benchmark in the metalworking sector of the state of Espírito Santo, delivering excellence in manufacturing, machining, industrial assembly, and services for the industry.

IMS POLICY

BNG Metalmecânica, within its field of operation, carries out machining, boiler-making, and painting processes with the objective of ensuring customer satisfaction, employee well-being, and sustainable business growth. For more details, please refer to our SGI policy below.

OUR VALUES

COMMITMENT

Engagement of all with the company’s mission, values, and strategic objectives.

ETHICS

Integrity-based relationships with clients, suppliers, and employees, aimed at inspiring trust and credibility.

HEALTH AND SAFETY

Providing safe working conditions aimed at ensuring the physical and psychological integrity of employees.

HUMAN VALUE

Commitment to continuous training and development of employees, making BNG Metalmecânica a company where everyone takes pride in working.

CUSTOMER FOCUS

Dedication and attention to customers’ needs, aiming to exceed expectations and strengthen trust in our products and services.

INNOVATION

Constant pursuit of new methods and technologies.

ENVIRONMENT

Work towards minimizing negative environmental aspects and impacts.

QUALITY

Commitment to the policy and continuous improvement of the effectiveness of the integrated management system.

OUR CERTIFICATIONS

Committed to excellence, we maintain the most important certifications in the sector, ensuring quality and safety in all our services.

Development and implementation of a Quality Manual aligned with the requirements of the ISO 9001:2015 standard

Conducting periodic internal audits and management reviews by top management to assess QMS performance

Monitoring quality indicators (rework rate, customer satisfaction, and performance targets) and generating management reports

Management of corrective and preventive actions to address non-conformities and continuous pursuit of process improvements

Certification for Quality Management Systems, attesting to our commitment to process excellence and customer satisfaction.

Process standardization

Continuous improvement

Increase in customer satisfaction

Reduction of non-conformities

Implementation of hazard mapping and occupational risk assessment, with a risk control matrix updated periodically.

Definition of operational controls, including safe work procedures, appropriate PPE, and emergency response plans.

Continuous monitoring of EHS performance indicators (incident rates, workplace accidents, and Safety Leaders) and analysis of non-conformities.

Periodic training and capacity-building program for all hierarchical levels in occupational safety practices.

PRODFOR SGSS System inspired by ISO 45001:2018 for Occupational Health and Safety Management, focusing on hazard identification processes, risk assessment and operational controls, demonstrating our ongoing commitment to the physical integrity of our employees.

Safer work environment

Reduction of workplace accidents

Compliance with legal requirements

Continuous improvement of safety processes

Padronização de critérios para seleção e qualificação de fornecedores, incluindo auditorias in loco

Strict quality control of raw materials and components through visual inspections and laboratory testing.

Batch traceability system with digitized records and management of supply documents.

Periodic evaluation of supplier performance and conduction of compliance audits.

Quality Management System in Supply, ensuring compliance with the standards required by major Brazilian industries.

Quality-assured supply guarantee.

Standardized and consistent processes.

Complete traceability of materials

Qualification for major industrial projects

OUR EQUIPMENT FLEET

Cranes and Muncks

Transports

OUR CLIENTS

We are proud to serve the largest companies in Brazil, contributing to the success of their projects and operations.

CONTACT US

We are ready to meet your needs. Get in touch with us and discover our customized solutions.